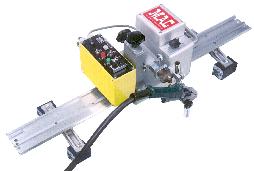

ALL POSITION TRAVEL CARRIAGE

MAKO  |

|

MAKO-Z2

| • |

One Pass Vertical Welding of 6~16mm thk. is possible. |

| • |

Owing to 2-axes Weaving, Unique Semi-elliptical Weaving Pattern is available. |

|

|

MAKO- Z

Simple automatic welding carriage for Vertical,Horizontal and Flat Welding

with function of interlocking with MIG and CO2 Welding Machine.

Features:

| • |

Portable & Light Weight |

| • |

Easy setting & Simple operation |

| • |

Compact Weaver is provided.

(Except MAKO-Z0) |

| • |

Vertical, Horizontal and Flat Welding are available

(MAKO-Z0: Flat Welding only) |

|

MAKO-Z 0 (ZERO)

| • |

Handy carriage for Flat Welding |

|

|

|

MAKO-Z1

| • |

One Pass Vertical Welding of 6mm thk. is possible. |

| • |

1-axis Weaving is provided. |

|

|

|

Specifications

Carriage

| Model |

MAKO-Z0-H |

MAKO-Z1-M |

MAKO-Z2-L |

MAKO-Z2-M |

| Traveling method |

Rail guide, Rack and Pinion |

| Traveling speed |

130 ~ 1,800mm/min |

40 ~ 500mm/min |

25 ~ 300mm/min |

40 ~ 500mm/min |

| Max. loading capacity |

10kgs |

5kgs |

3kgs |

3kgs |

| Speed regulating method |

By Potentiometer through Thyristor control |

| Driving motor |

40W DC Motor |

| Rapid traversing |

By manual through Mechanical Clutch |

| Torch fine-adjustment |

Right/Left: 50mm By manual

Up/Down: 100mm By manual |

| Automatic stop function |

Provided (By Limit Switch, both direction)

Striker position can be adjustable. |

| Switches |

Power On/Off, Travel-direction change-over switch,

Digital Speed Regulating Dial,

Weld/Non-weld Changeover Switch,

Weld-Start, Weld-Stop |

| Crater-treatment function |

Not provided |

| Power source |

AC100V., 50/60Hz., 1-Phase |

| Power cable |

3M |

| Torch switch cable |

6M |

| Dimensions (W×L×H) |

348×454×276mm

w/out Weaver |

379×519×276mm

With Weaver |

473×519×276mm

With Weaver |

473×519×276mm

With Weaver |

| Overall weight |

11.5kgs

w/out Weaver |

16kgs

With Weaver |

18.5kgs

With Weaver |

18.5kgs

With Weaver |

Note: Contact us for Crater-treatment function and for TIG Welding. |

Compact Weaver

| Model |

WV- 1A

(for MAKO-1) |

WV- 2A

(for MAKO-2) |

Weaving speed

(times/min.) |

30 ~ 150 |

15 ~ 70 |

Weaving Width

(X-Axis) |

±5.1º |

0 ~ 30mm |

Weaving Depth

(Y-Axis) |

— |

0 ~ 15mm |

| Weaving Pattern |

Pendulum pattern |

Linear and Semielliptical

pattern |

Width Adjusting

Method |

By manual knob |

Depth Adjusting

Method |

— |

By manual knob |

| Dwell time |

0 ~ 1.0 sec. |

| Dwell Position |

Right, Center and Left (Individually) |

| Switches |

Power On/Off, Operation On/Off,

Speed regulating dial, Dwell On/Off,

Dwell time regulating dial

(Right, Center and Left, Individually) |

| Weight of weaving head |

2.7kgs |

4.7kgs |

|

|

Rail

Dimension

W × L (mm) |

100×2,000

(Aluminum extrusion material) |

| Attracting method |

By 6 permanent magnets

(Unclamp lever is provided) |

| Attractive force |

980N (100kgf) /magnet |

| Rail Joint |

Possible (No Tool required) |

| Weight |

12kgs |

Note: 1)1,000mm Rail with 4 magnet is OPTION.

2)Above attractive force is on condition more than

6mmthk.,Mild steel and Clean surface.

|

Specifications are subject change without prior notice. |

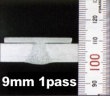

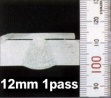

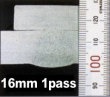

Welding conditions and Macrograph of Vertical Welding by MAKO-2

Number of pass: One pass, Material: Mild Steel

| Thickness |

6mm |

9mm |

12mm |

16mm |

| Angle |

V60º |

V60º |

V60º |

V40º |

| Root face |

2mm |

2mm |

2mm |

0mm |

| Gap |

3mm |

2mm |

2mm |

5mm |

| Backing thk. |

3mm |

3mm |

3mm |

10mm |

| Shield gas |

CO2 Gas 20 Litre/min. |

| Wire |

Flux-cored wire for vertical welding (V-type), 1.2mm |

| Welding speed |

110mm/min. |

110mm/min. |

70mm/min. |

42mm/min. |

| Welding current |

140A |

170A |

170A |

200A |

| Macrograph |

|

|

|

|

|