SEAM TRACKING UNIT

—SUPER GUIDE—  |

|

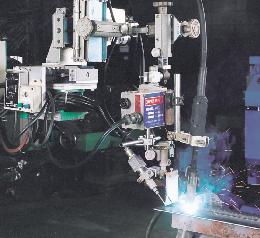

Deviation between welding line and torch position is a major problem in

welding, and welding defects (such as, Overlap, Undercut, lack of fusion,

etc.) are often caused by this deviation. The deviation are caused from

poor machining & cutting accuracy of grooving, poor accuracy of tack-welding,

strain while welding. Purpose of SUPER GUIDE is to correct the deviation

between welding line and torch position by following of torch to welding

line. SUPER GUIDE consists of Control box, Remote-control pendant, Cross-slide

unit (horizontal and vertical), Sensing Probe and Probe mounting assy.

Sensing probe track the position of the joint, then translate these signals

into Cross-slide unit through Control box to assure accurate positioning

of the torch. SUPER GUIDE can be installed on standard welding jigs (such

as Manipulators, Torch Stand, Positioners, etc.) and also adapted to most

custom-made welding jigs.

|

WSG-1200 |

3 Main Featurs;

1. Tack-welding bead Cut-Off Mode

When the probe detect tack-welding (rapid rises-up motion of the probe by tack-welding bead, etc.), control of cross-slide unit become off.

Resulting, the torch keep same height (Same Arc-length) and Constant bead is formed. The control become on when the timer times out. |

When the probe detect tackwelding, the torch rise up at the same time.

Resulting, welding defects may occurs. |

2. End of Work-piece Cut-Off Mode

When the probe come to end of work-piece and falls down (rapid falldown

motion of the probe),control of cross-slide unit become off.

Resulting, the torch continue to move and keep same height. |

The control of cross-slide unit does not become off at workpiece end. So,

the probe and torch fall down together. |

3. Side-track Cut-Off Mode for Fillet Welding

The probe fall down straightly first, then move to the right or left to

detect Fillet

Welding Line securely. |

The prove fall down aslant.

Therefore, the probe may detect different Fillet Welding Line. |

|

Specifications

| Model |

WSG- 1200 |

WSG- 2200 |

| Purpose |

for CO2/MAG/

MIG Welding M/c. |

for Submerged

Welding M/c |

| Power supply |

AC 100V., 50/60Hz., 1-Phase |

| Max. loading capacity |

25kgs |

75kgs |

| Tracking speed |

130mm/min (50Hz)

160mm/min (60Hz) |

120mm/min (50Hz)

150mm/min (60Hz) |

| Tracking stroke |

100mm (±50mm) |

150mm(±75mm) |

Control

mode |

Manual-mode |

UP/DOWN and RIGHT/LEFT |

Automatic-

mode |

Both-direction tracking,

Left-tracking, Right-tracking,

Tack-welding bead cut-off mode,

End of work-piece Cut-Off Mode,

Probe-center indicator. |

| Cross-slide drive system |

Motor-driven through screw-shaft |

| Driving motor |

6W Reversible motor |

25W Reversible motor |

Note: Specifications are subject to change without prior notice. |

|

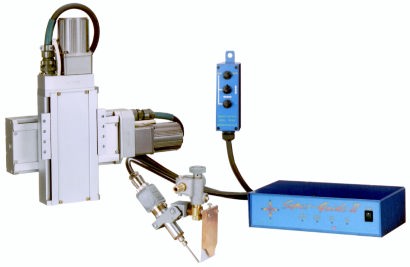

Composition

| Descriptions |

Model |

Qty. |

Weight (kgs) |

| Control box |

WS-120-1

(WS-120-2) |

1 set |

7.0 |

Remote-control

pendant |

WS-420 |

1 pc. |

0.9 |

| Cross-slide unit |

MS-110SB

(SG-215CL) |

1 set

(2 pcs.) |

5.0

(11.5) |

| Sensing probe |

WS-210

(WS-220) |

1 pc. |

0.3

(0.5) |

| Adjuster |

WS-310 |

1 set |

0.8 |

| Control cable |

— |

1 set |

— |

* Figures in parenthesis are for WSG-2200.

Note: Specifications are subject to change without

prior notice. |

|