| CNC PIPE PROFILE CUTTING M/C |

|

Features:

| • |

Simple Operation: MAC's CNC Pipe Profile Cutting M/c eliminates the need to layout and construct

complicated pipe wraps and patterns. The operator simply inputs data, such

as pipe diameter and thickness, etc into the control by a hand held teach

pendant. The CNC Control them makes all the required calculations to accurately

cut the desired joint type. Quick and easy to use even if only one cut

is desired. |

| • |

Accurate Cutting: Due to the accurate cuts, all grinding and additional fit-up work associated

with manual cutting is eliminated. |

| • |

Cost Effective: MAC's CNC Pipe Profile Cutting M/c dramatically cuts the man hours and operator skill needed to cut accurate pipe joints. Weld quality is also increased due to the ability to make a more consistent accurate fitting joint than can be done manually. The large cost savings in labor leads to a short payback time for the machine. |

| • |

Excellent Reliability: Features full digital control with the combination of high quality AC Servo Motors and Computer Control. Heavy-duty construction combined with high quality materials and workmanship lead to years of trouble free service. |

| • |

Large Spindle Hole: MAC's CNC Pipe Profile Cutting Machines have the unique ability make cuts

at any point on long pieces of pipe and tubing due the large spindle hole.

Each machine features self-centering chucks for quick and positive loading

and unloading. |

| • |

Options: A wide range of optional software is available. |

Video(Japanese) - The former model - Video(Japanese) - The former model - |

|

|

|

PCM-330

• 3-Axes (Rotation, Right/Left and Torch-Twisting)

• Bevel-cutting and Miter-Cutting is possible.

• Max. pipe dia.: 318.5mmOD |

|

Dimension: W1,550 X D1,050 X H1,400mm

Weight: 1,000kg |

T-Joint Hole Cut(Inner-Fit) |

T-Joint End Cut(Center) |

|

|

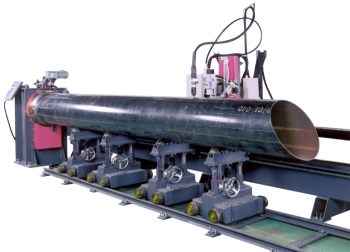

PCM- 460

• 4-Axes (Rotation, Right/Left and Torch-Twisting & Up/Down)

• Bevel-cutting and Miter-Cutting is possible.

• Max. pipe dia.: 609.6mmOD

|

|

|

Dimension: W2,400 X D1,500 X H2,100mm

Weight: 1,500kg

*Gas Cutting Torch is OPTION. |

|

T-Joint End Cut(Center) |

|

| AUTOMATIC TYPE |

PCM- 660

PCM- 690

PCM- 6135 |

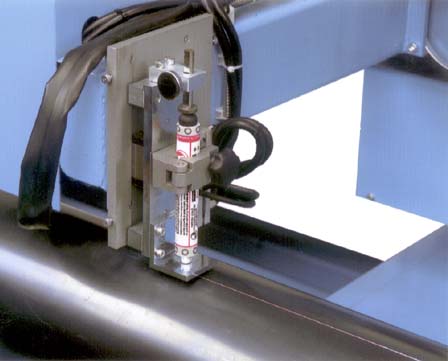

• 6-Axes (Rotation, Right/Left, Torch-Twisting, Up/Down, Torch-Lifting

and Front/Rear)

• Pipe Upper-surface Touch Sensor and Pipe Side-surface Touch Sensor

for an inaccurate pipe

• Max. 99 cutting conditions can be recorded.

• Making and handling cutting conditions can be performed by Computer. |

|

Pipe Upper-surface Touch Sensor

|

Pipe Side-surface Torch Sensor |

|

Marking Function (OPTION)

|

|

|